It is known that metallic minerals behave differently in the process of flotation with different collectors. One can notice that there is a significant difference in selectivity xanthate and aeropromoter on copper ore. Results of the research conducted in ITNMS, shows that by applying the collector aeropromoter, we get copper concentrates with a much worse distribution of sulfur in relation to the case when applied as a xanthate collector. Statistical analysis can prove that there really is a difference in extraction selectivity of Cu and S from the ore, which is the result of various activities of the various surfaces of metallic minerals when they are prepared by Mechanochemistry treatment of flotation There is also a difference in the effect of the xanthate and aeroflot also activated the surface because the very diversity of reagents. The answer to this outcome study [1,2,3,4] we looked at different thermal conductivity and thermal diffusivity and heat transfer capabilities of metallic minerals is given by the formula:

Where:

cp - specific heat conductivity at constant pressure, J / (mol K)

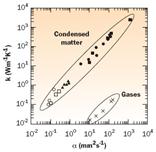

Fig.1. Thermal conductivity and thermal diffusivity;

Fig.2. Energy and reaction time at mechanochemistry treatment;

Fig.3. Pressure and volume changes in Mechanochemistry treatment;

The diagram in Figure one shows that in different aggregate states of matter, liquid, solid and gaseous, are different values of thermal diffusivity and the molecular size of the heat conduction. By Mechanochemistry activation we have a situation that increases the molecular thermal diffusivity due to a decrease the density.

Mechanochemistry treatment has role as a catalyst, and a process of adsorption is being carried out very quickly because it has a shorter reaction time (red dashed line), in the cases when this happens without changing the chemical potential (black solid line). Maximum point on the diagram 2 becomes lower when by the Mechanochemistry treatment we increase energy in solid matter the amount of Gibbs's free energy. Then the barrier crossing reaction XY and YX is smaller and more easily accomplished, or can be achieved in devices with lower specific power.

The active properties of mineral surfaces resulting in a system of flotation pulp (highly complex multi-phase disperse systems) where the kinetic energy of mechanochemistry treatment converted into heat in direct contact, and convert to the solid mineral matter and vice versa.

Collaborators on the project:

Vladimir Jovanović, Research Associate,

Ljubiša Andrić, Research Fellow,

Vladan Milošević, Research Fellow,

Slavica Mihajlović, Research Fellow,

MiodragGajić, consultant,

Melina Vukadinović, senior associate,

Zoran Bartulović, Research Associate,

Ivana Jovanović Research Associate,

Dejan Todorović, Research Fellow,

Milena Kostović, Associate Professor.